Number of views:

1000

Membrane Plate

Retail price

0.0

Yuan

Market price

0.0

Yuan

Number of views:

1000

Product serial number

Quantity

-

+

Stock:

Product Details

Parameters

The diaphragm filter plate of our company has won many national patents and is widely used in solid-liquid separation in various industrial fields. Its main features are as follows:

(1) low pressure filtration, effectively shorten the filtration cycle and improve productivity.

(2) medium pressure filtration, effectively shorten the washing cycle, improve productivity.

(3) high pressure filtration can more effectively reduce the moisture content of filter cake, reduce energy consumption or increase the yield.

(4) diaphragm replaceable diaphragm filter plate, good sealing performance, easy to disassemble and replace, can greatly reduce the cost of the production process.

(5) special processing technology, specific imported materials, long service life of filter plate.

The diaphragm filter plate is composed of two diaphragm plates and core plate, which is fed into the external medium (water or compressed air, etc.) into the chamber between the core plate and the diaphragm to make the diaphragm bulge, so as to compress the filter chamber composed of diaphragm filter plate and chamber filter plate, so as to better separate and improve the solid content. The diaphragm is the main moving part, and repeated movement is easy to cause deformation and damage of the diaphragm.

Diaphragm plate is divided into rubber diaphragm plate and polypropylene diaphragm plate. Rubber diaphragm filter plate diaphragm is generally embedded in the core of the groove, easy to remove and replace, because the rubber diaphragm has a high degree of elasticity, so not easy to damage. The diaphragm of polypropylene filter plate is generally welded in one piece. The diaphragm formed by welding shall not be replaced.

Advantages

1. Short filtering time

With the increase of filtration time, the filter cake grows slower and slower. In order to make the residual humidity in the filter residue low, the filter plate frame and the box filter plate need a longer filtering time; The use of JVK diaphragm filter plate can greatly reduce the filtration time. The required residual humidity is achieved by mechanical extrusion of the elastic diaphragm.

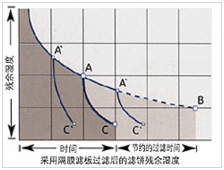

Residual humidity after filtration of diaphragm filter plate:

A= diaphragm plate filtration end point

B= end point of wing filter

C= residual humidity after extrusion of diaphragm filter plate

A 'and C' are different possible outcomes depending on the operation

Suitable operation point A can be determined after several filtration cycles.

2. Short washing time

The use of common filter elements can cause uneven cake formation, such as uneven washing due to wrinkling or cracking. The JVK diaphragm filter plate avoids this unevenness due to the light pressure of the diaphragm during the washing process. Because of the uniform capillary structure formed in the filter cake, the washing effect is very good, and the consumption of washing liquid can be greatly reduced.

3. Low residual humidity

The high pressure filtration required in the filtration process is replaced by a high elastic membrane extrusion process on the filter cake. The extrusion process is not along the direction of the filter surface, but across the filter surface. In a short time, the residual humidity in the filter cake decreased significantly, and the filtrate outflow increased significantly. The benefits are as follows:

It saves energy costs

A special vacuum process results in a solid content of almost 100%

The blow-drying process is shortened

The filter cake sticks less to the press cloth

The discharging time of filter cake is obviously shortened

The filtering process can be automated

Lower pump costs

Because the filter cake is compact and dry, the transportation cost is reduced

Savings in storage costs

4. Diaphragm replaceable

The diaphragm can be easily replaced inside or outside the filter press. If the diaphragm is damaged on either side of the traditional diaphragm plate, the entire diaphragm plate should be replaced. Diaphragm plate is a moving part of the plate, the maintenance costs need to be considered. The removable diaphragm plate on either side can be replaced separately, and the core plate continues to be used, greatly reducing maintenance and replacement costs.

5. The closing force of the filter press does not directly act on the diaphragm

The diaphragm edge extends only to the seal of the diaphragm plate core plate itself. Therefore, the closing force of the filter press does not act on the diaphragm, but only on the sealing surface of the filter plate core plate.

6. High elasticity of the diaphragm

Because of the good elasticity of the membrane, the membrane can adjust itself without permanent deformation for the uneven filter cake surface formed during filtration and the filter cake membrane with different packing density. This feature ensures even and good cake extrusion. JVK diaphragm filter plate pressure up to 60bar, to meet a variety of industrial applications.

7. Even in the cavity state, the diaphragm movement will not be out of order

The diaphragm is held in place where there is no stress. The > diaphragm can be squeezed into the cavity without failure, regardless of the chamber depth.

The diaphragm filter plate of JVK has no bolted connection and is completely sealed by the rubber diaphragm itself. Even if the filter press is turned on when pressure is applied in the chamber of the diaphragm chamber by mistake, the diaphragm on the JVK diaphragm plate will eject the filter plate according to the pressure to release the pressure, and only need to be newly installed. The traditional diaphragm plate is usually welded or bolted, which inevitably causes damage.

8. There is no time limit for diaphragm movement

In some cases, the gradual increase and decrease of pressure during feeding, washing and pressing can be neglected. This process can be optimized with JVK diaphragm plates.

9. The filter plate system has good tightness

The filter plate core plate sealing process is performed in accordance with the German industry standard DIN 7129. The diaphragm is secured on the periphery, so the chamber seals very well. The CGR design structure is a completely sealed structure of the JVK diaphragm filter plate.

10. Large filtrate outlet passage section

The diameter and number of filtrate outflow channels from the filter surface to the core of the filter plate are set according to the requirements of the application. The diameter of the outlet channel can be up to 10mm, so the filtrate discharge can be large, without solid particles or crystals blocking the outlet channel.

11. Wide range of applications

The raw materials used at JVK ensure that the product can be used in almost all industries and can be adapted to each specific working condition. With diaphragm made of special elastomer and diaphragm plate core made of special material, JVK diaphragm plate can be used for:

The temperature ranges from -20°C to +140°C

Filtration pressure up to 15bar

Press pressure to at least 25bar

Extreme temperature change (sudden change in temperature)

Special chemical requirements

12. High safety of diaphragm system

There is no screw or welded connection between the diaphragm and the sealing surface of the core plate. The pressure of the extruded media behind the diaphragm can only be maintained by a closed filter press. If the filter press is open or just opened, but there is pressure in the diaphragm, the diaphragm will immediately move away from the fixed groove, resulting in a non-dangerous release of pressure without damaging the diaphragm. The cost of security maintenance has been significantly reduced.

Scan the QR code to read on your phone

Sales Department Phone:+86-318-2028087

Fax:+86-318-2186861

E-mail:hshhhb@126.com

Address: No. 29 South Zhouxiying Village, Hempeng Township, High-tech Zone, Hengshui City

Code:053000

-Visit mobile-

Copyright © 2019 Hengshui Haihong Environmental Protection Equipment Manufacturing Co., Ltd.